2021 wholesale price H&C Concrete Construction Group - 120 Steel frame formwork – Lianggong

2021 wholesale price H&C Concrete Construction Group - 120 Steel frame formwork – Lianggong Detail:

Product Details

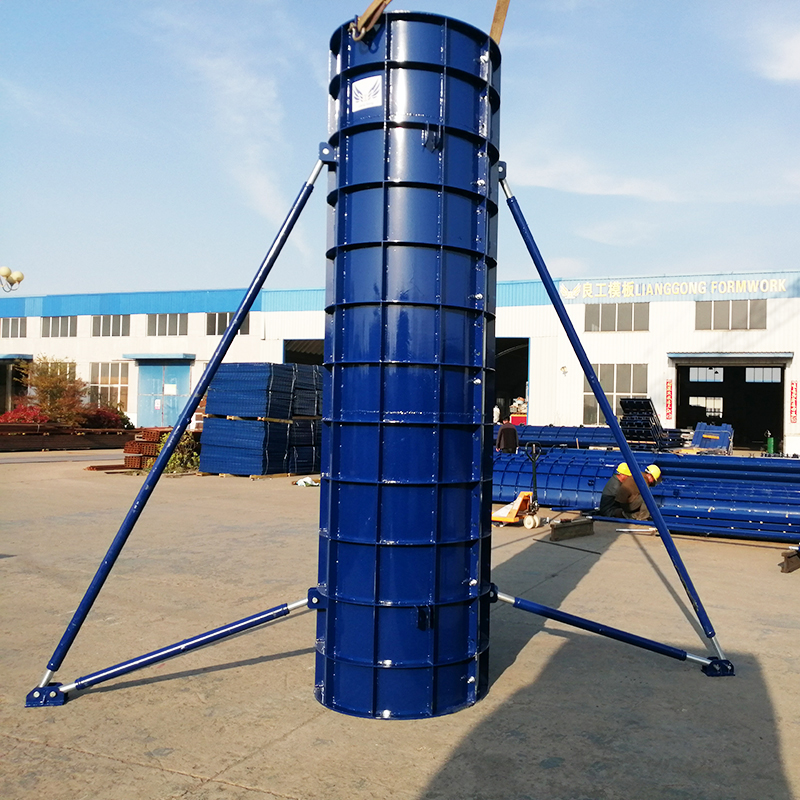

120 Steel frame system Including Plywood, no Pre-assembly of the system required.

Mainly Used for all types of walls such as Shear walls, Core walls as well as for various sizes of Columns for Various heights.

The 120 Steel frame system is a Steel framed Panel System, which is ready for use and very rugged.

The 3.30m, 2.70m and 1.20m panels have various widths from 0.30m to 2.4m with 0.05m or 0.15m intervals the panel width size can apply with all application efficiency.

All 120 Steel frame system are based on cold roll-forming profile for the edges. Theses edge profile is prepared with a special shaping on the inside that allows application of the alignment Couple.

The holes are provided in the vertical edge profiles exact alignment of the erected panel is made possible through the recess of the edge profile by using a crowbar (or nail-remover).

The 18mm thick plywood sheet is supported by eight or ten intermediate bars of equal design. They also offer numerous possibilities for the attachment of 120 Steel frame system accessories. The Steel frame is completely painted.

All the panels can be combined in the various ways, lying on their sides or standing upright. They can also be installed in a staggered arrangement as their interconnection is independent of any dimension modules.

A panel depth of 12cm guarantees good load-bearing capacity (70 KN/m2) So that a Single-Story formwork of 2.70 and 3.30 meters height, concrete pressure and rate of concrete placing need not be taken into consideration. The 18mm thick plywood is glued 7-fold and when casting against masonry walls.

Characteristics

All components are ready to use upon arrival at the site.

Special profiles which from the frame, increase the strength of the panel and ensure a long service life .By means of special shaped profiles and one blow clamps, panel connections are very easy & quick.

Panel connection is not dependent on the holes on the frame profiles.

The frame surrounds the plywood and protects plywood’s edges from unwanted injuries. A few clamps are enough for a rigid connection. This ensures to shorten the assembly and disassembly period.

The frame prevents the water to get into the plywood through its sides.

120 Steel frame system consists of steel frame, plywood panel, push pull prop, scaffold bracket, alignment coupler, compensation waler, tie rod, lifting hook, etc.

Plywood panels is made with a wisa form plywood with high quality .the steel frames therein are made of special cold roll forming steel

Compensation waler strengthens its integrate rigidity at panel connection location.

Easy operation, light weight, convenient storage and transportation.

Using the components included in the basic system, you will be able to solve formwork problems in industrial and housing construction.

The parts included in the additional components widen the application possibilities of formwork and simplify concreting.

Non-rectangular corners can simply be shuttered with hinged corners and the outer corners. The adjustment range of these components permits oblique angular corners, adjusting members compensate for differing wall thicknesses.

Application

Product detail pictures:

Related Product Guide:

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for 2021 wholesale price H&C Concrete Construction Group - 120 Steel frame formwork – Lianggong , The product will supply to all over the world, such as: Uganda, Mali, South Korea, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.