China Factory for Exterior Wood Beams - H20 Timber Beam Column Formwork – Lianggong

China Factory for Exterior Wood Beams - H20 Timber Beam Column Formwork – Lianggong Detail:

Product Details

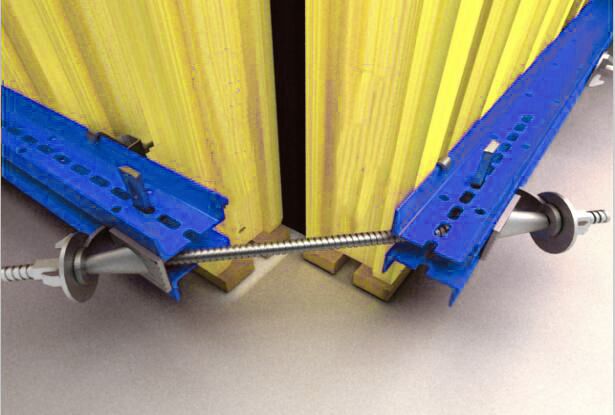

The timber beam column formwork is mainly used for casting columns, and its structure and connecting way are quite similar to that of wall formwork.High flexibility with only a few main components can meet any construction requirements, such as timber beam H20, steel waling, plywood and clamp etc.

| Material | Q235 Steel, Timber Beam, Plywood |

| Color | Customized Or Yellow,Blue,Brown |

| Size | Universal Forming |

Technical Specification

Max. permissable pressure is 80kN/m2

Easy to take any fresh concrete pressure by adjusting layout space between H20 and walers

Max.Cross section is 1.0mx1.0m without in-through tie rod

Flexible adjustment to fit different column dimension

Timber beam adjustable column formwork

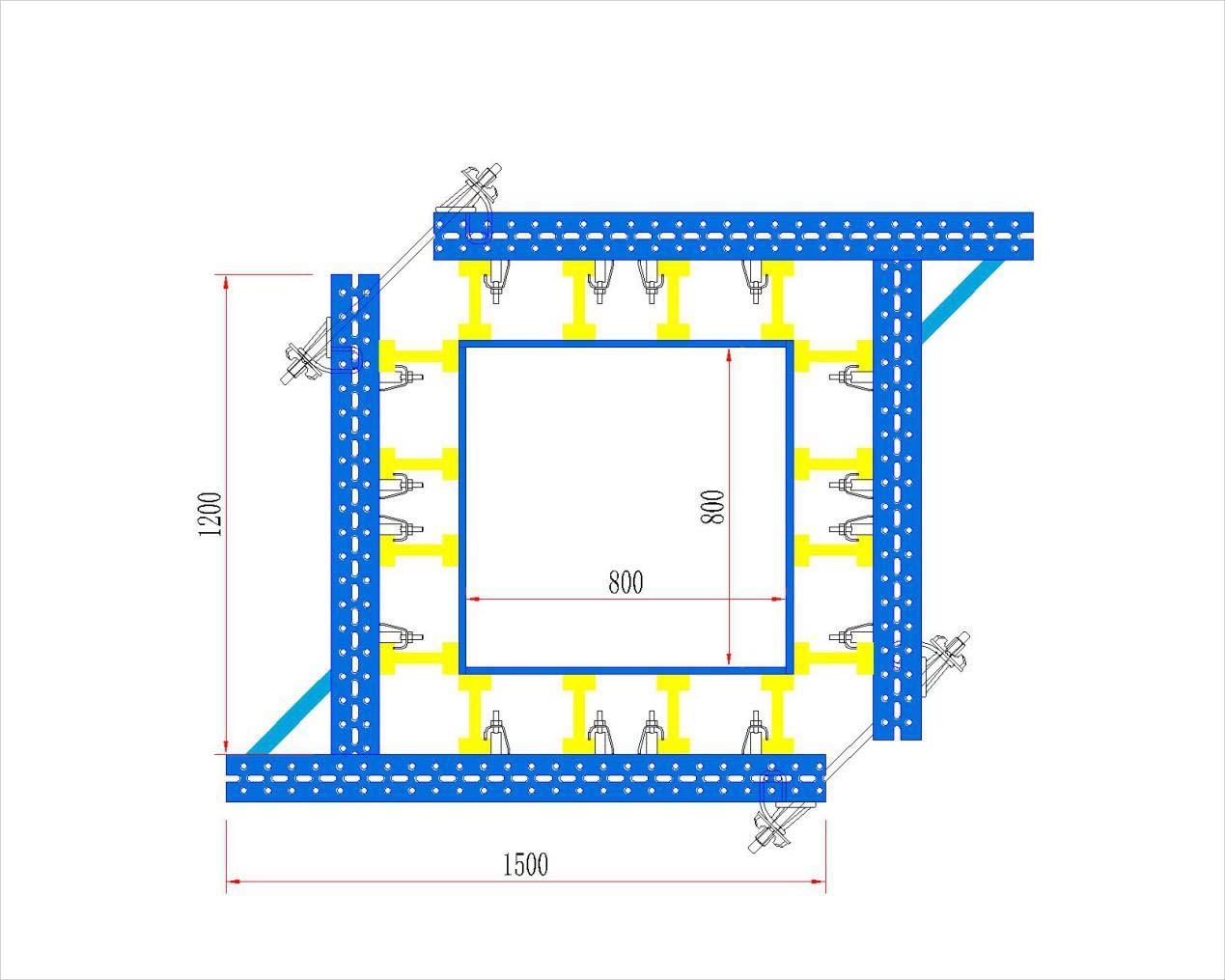

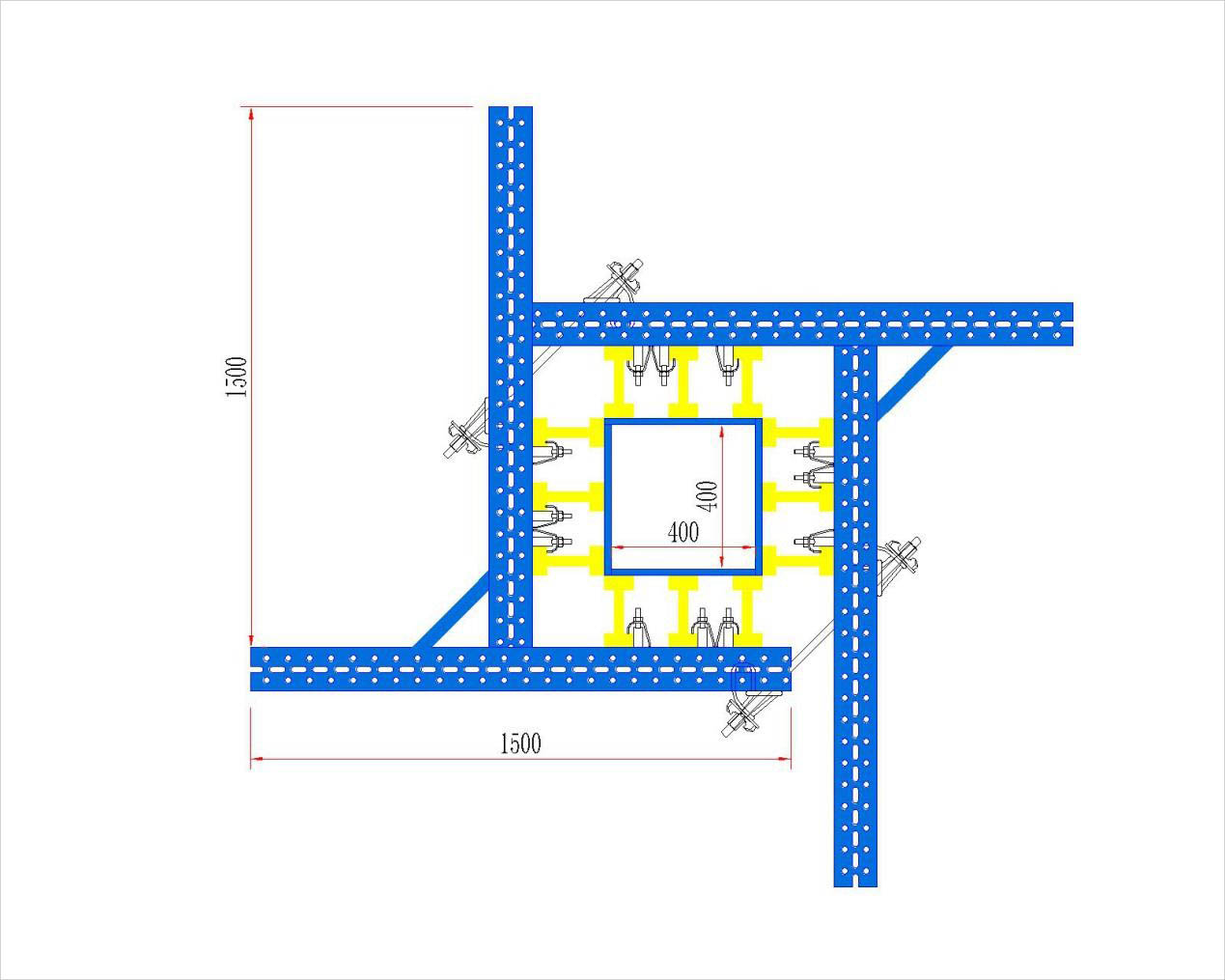

The adjustable column formwork enables concrete casting of square or rectangular columns within a specific range by adjusting the size of the formwork section area. The adjustment is realized by changing the relative position of the walers.

There are three specifications for the walers of adjustable column formwork, which can do concrete casting of square or rectangular columns with side length of 200-1400mm. Sizes of column to be casted as follows:

|

Length of waler (m) |

Scope of side length of column to be casted (m) |

|

1.6 and 1.9 |

1.0 ~ 1.4 |

|

1.6 and 1.3 |

0.6 ~ 1.0 |

|

1.3 and 0.9 |

0.2 ~ 0.6 |

It can be adjusted to any cross-section size within the allowable range, both square and rectangular. The schematic diagram of adjustment is as follows:

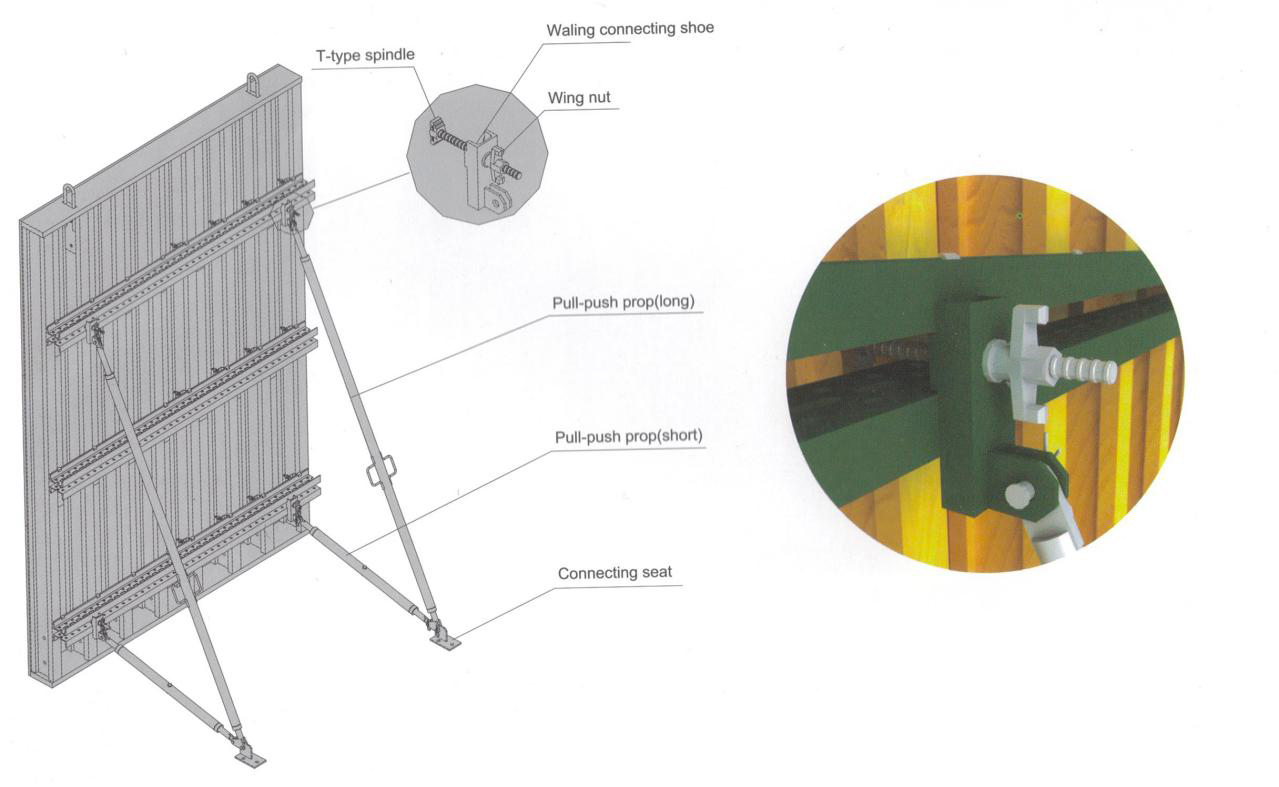

Wall diagonal brace

The timber beam wall column formwork needs to be equipped with a spindle strut, which is used as an adjusting system as shown in the figure:

Application

Our Service

Provide support in every stage of projects

1. Provide cosult when client take part in projects bid invitation.

2. Provide optimized formwork tender solution to assitant client to win the project.

3. Developing formwork design, refining initial plan, and exploring relation limit between supply&demand.

4. Start to design the formwork detailedly according to the winning bidding.

5. Provide economic formwork solution package and provide continous on-site support service.

Packing

1. Generally, the total net weight of loaded container is 22 tons to 26 tons, which need be confirmed before loading.

2. Different packages are used for different products:

—bundles: timber beam, steel props, tie rod, etc.

—pallet: small parts will be put in bags and then on pallets.

—wooden cases: it is available on customer’s request.

—bulk: some irregular goods will be loaded in bulk in container.

Delivery

1. Production: For full container, normally we need 20-30 days after receive customer’s down payment.

2. Transportation: It depends on the destination charge port.

3. Negotiation is needed for special requirements.

Product detail pictures:

Related Product Guide:

In an effort to finest meet up with client's requirements, all of our operations are strictly performed in line with our motto "High High quality, Competitive Rate, Fast Service" for China Factory for Exterior Wood Beams - H20 Timber Beam Column Formwork – Lianggong , The product will supply to all over the world, such as: Russia, Myanmar, South Korea, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ‘customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

A good manufacturers, we have cooperated twice, good quality and good service attitude.