As the western extension of the Hong Kong-Zhuhai-Macao Bridge, the Huangmao Sea Channel Bridge promotes the strategy of “a country with strong transportation network”, builds the transportation network of the Guangdong-Hong Kong-Macao Greater Bay Area (GBA), and connects the major projects of the Guangdong coastal economic belt during the 13th Five-Year Plan period.

The route starts from Pingsha Town of Gaolan Port, Economic Zone in Zhuhai, crosses the waters of Huang Mao Sea at Yamen entrance to the west, passes by Chixi Town of Taishan of Jiangmen, and finally reaches Zhonghe Village of Doushan Town of Taishan.

The total length of the project is about 31 kilometers, of which the sea-crossing section is about 14 kilometers, and there are two 700-meter super-large cable-stayed bridges. One middle tunnel and one long tunnel. There are 4 interchanges. The project was approved and estimated at about 13 billion yuan. The project officially started on June 6, 2020, and is expected to be completed by 2024.

Today we will be focusing on the inner formwork of Huang Mao Sea Channel Bridge. As a leading formwork & scaffolding manufacturer in China, Lianggong provides technical support for the on-site application and inner formwork systems for this project. Below is the the breakdown of today’s article:

1.Structure Diagrams of Huangmao Sea Channel Bridge

2.The Components of the Inner Formwork

3.The Assembling of Inner Formwork

4.The Structure of the Bracket System

On-Site Application Pictures

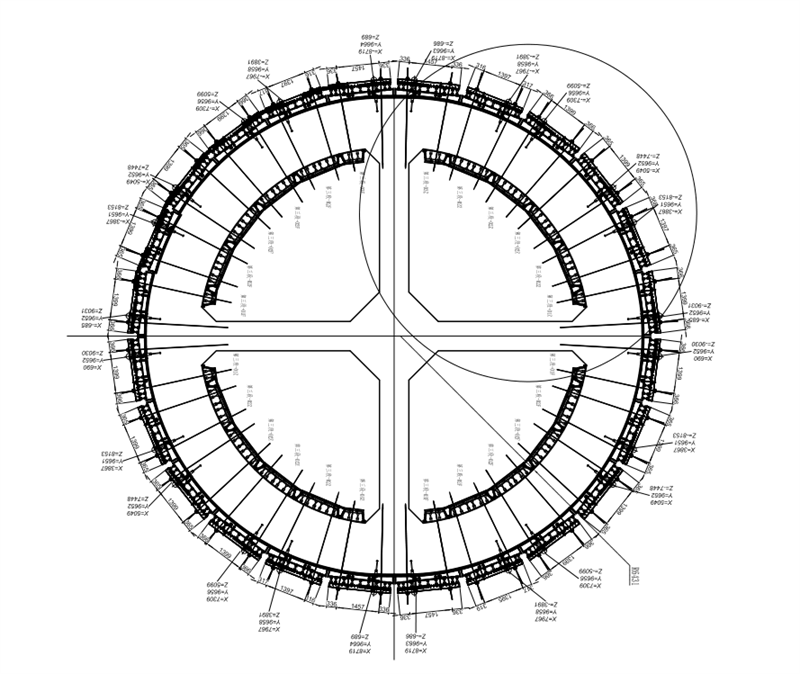

Structure Diagrams of Huangmao Sea Channel Bridge:

General Diagram

Diagram of Inner Formwork

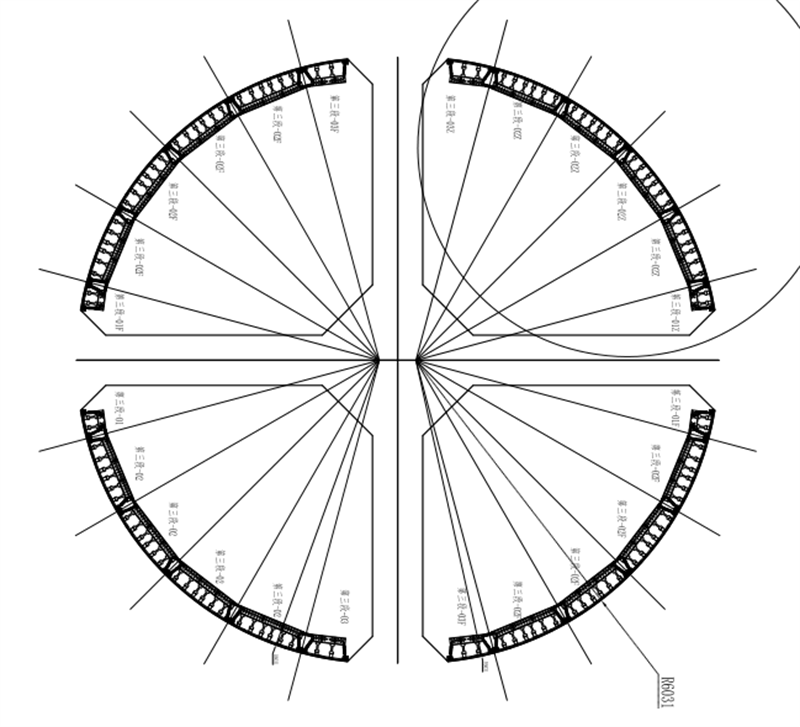

Assembling Diagram

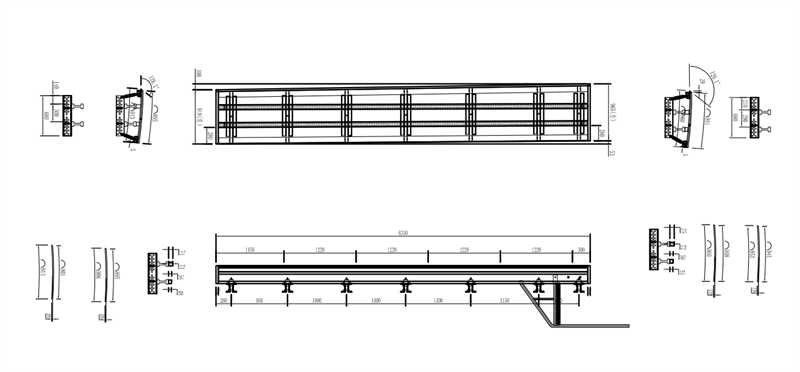

The Components of Inner Formwork:

The Assembling of Inner Formwork:

Step 1:

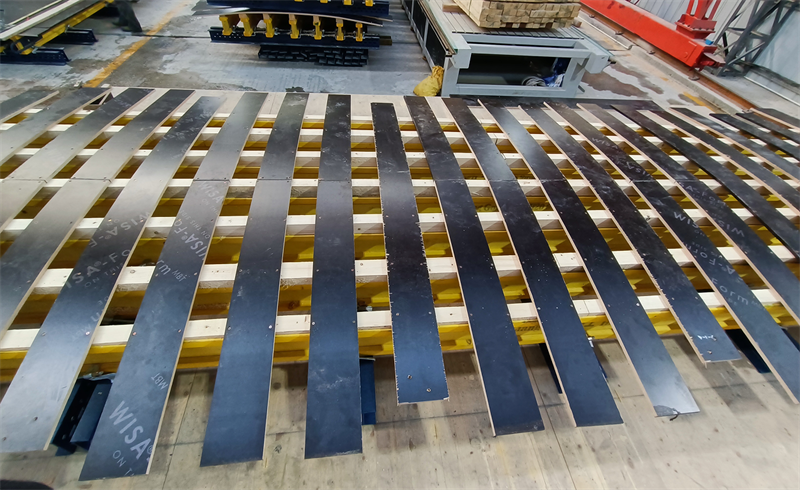

1.Lay the walers according to the diagram.

2.Put the timber beam on the walers.

3.Fix the flange clamp.

Step 2:

Fix the modelling wood according to the diagram’s dimensions.

Step 3:

According to the diagram, it requires opposite nailing. So nail the slats first.

Step 4:

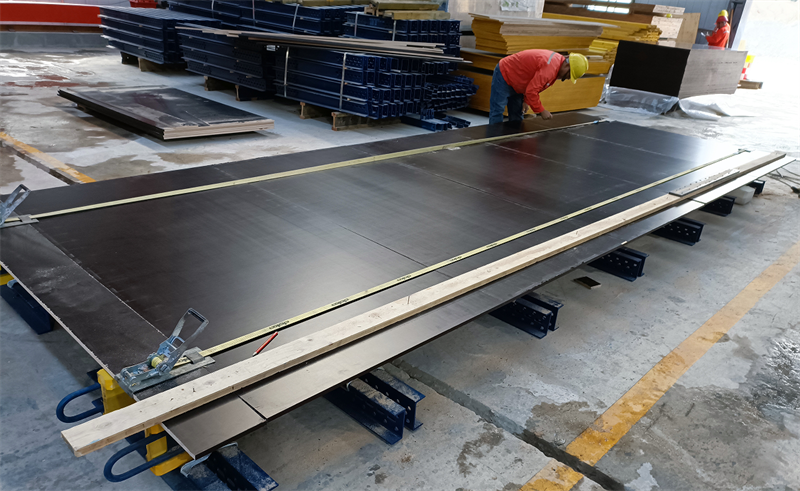

When the formwork is fixed, tailor it according to the required dimensions.

Step 5:

After the tailoring, fix the corner waler.

Step 6:

The plywood is joined to the timber beam’s body section with the adjusting screw.

Step 7:

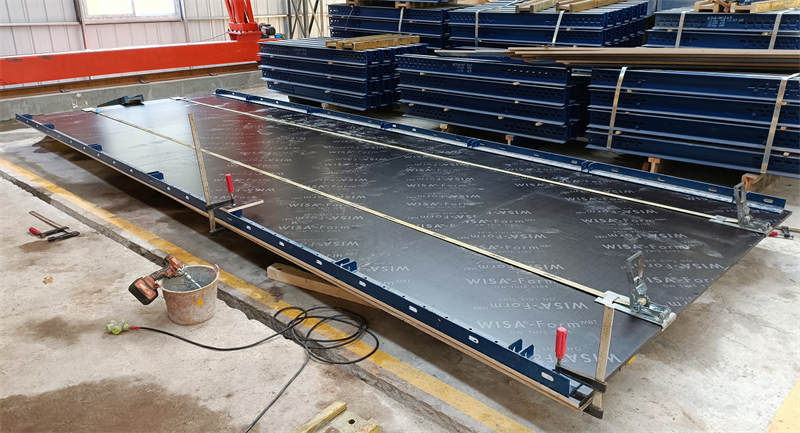

Fix the adjusting spindle.

Step 8:

Nail the plywood from the opposite side, then the basic formwork assembling is completed. Pile the formwork in order and cover it with the waterproof cloth.

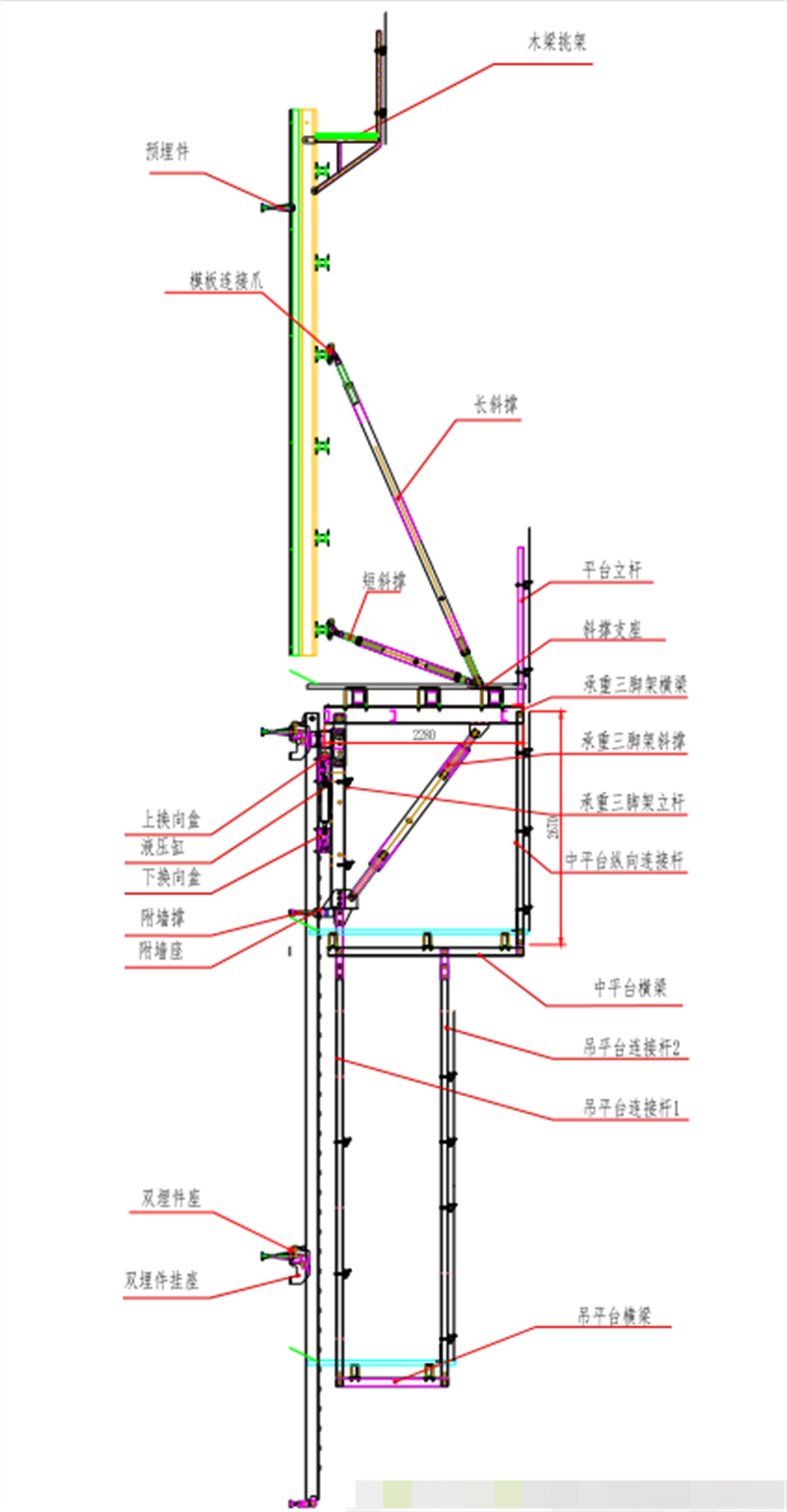

The Structure of the Bracket System:

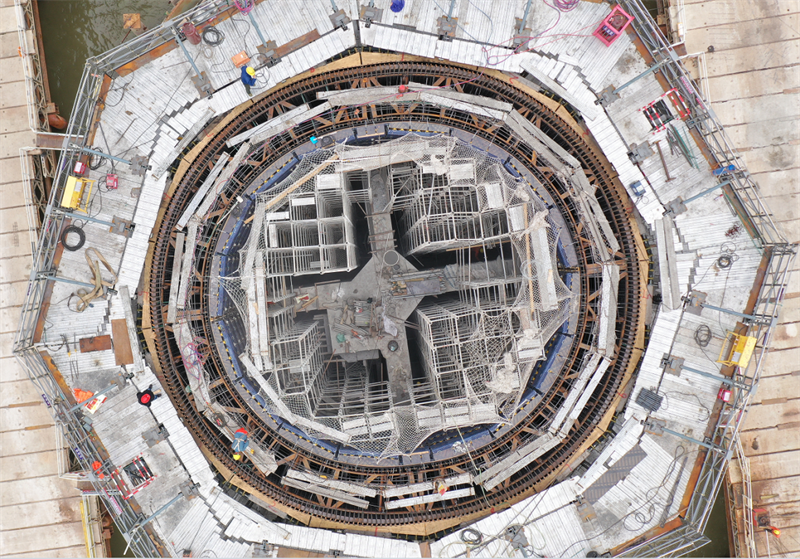

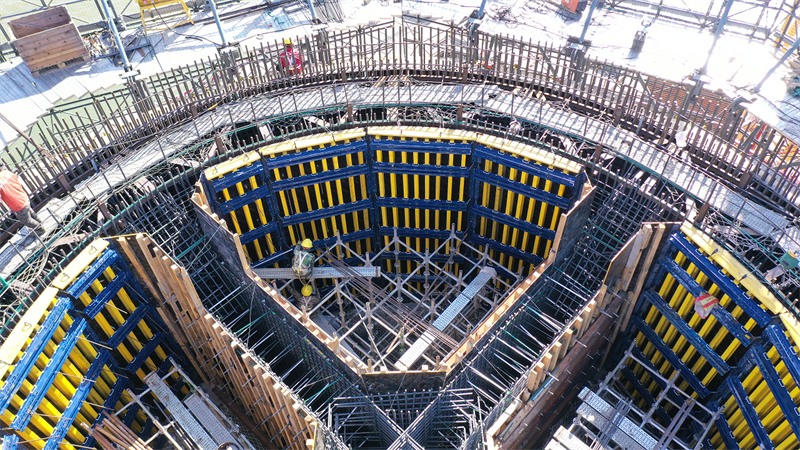

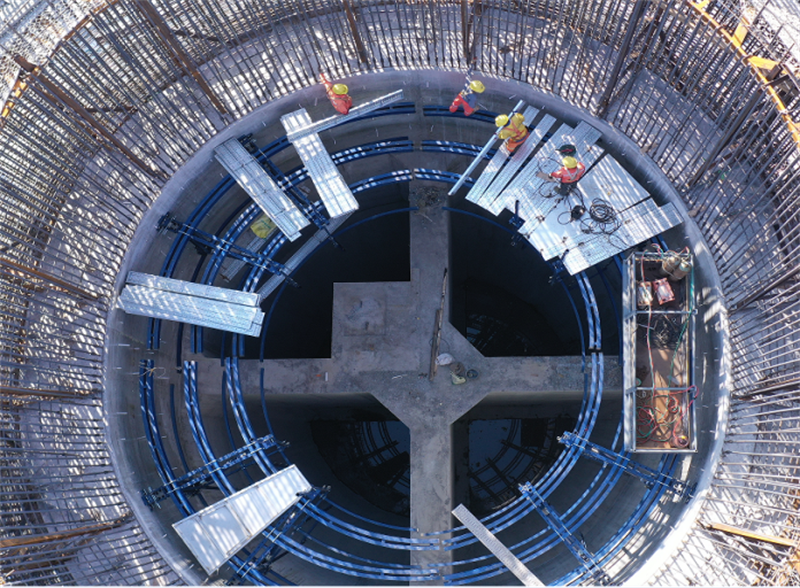

On-Site Application Pictures:

To sum up, Huangmao Sea Channel Bridge has applied lots of our products such as H20 Timber Beam, Hydraulic Auto-Climbing Formwork, Steel Formwork etc. We warmly welcome visitors from all over the world to come to our factory and sincerely hope we can do business together under the principle of mutual benefit.

Post time: Jan-21-2022