The hydraulic auto-climbing formwork LG-120, combining formwork with bracket, is a wall-attached self-climbing formwork, which is powered by its own hydraulic lifting system. With the help of it, the main bracket and climbing rail can either work as a complete set or climb respectively. Being easy to operate and dismantle, the system can improve your working efficiency and achieve fair-faced concrete results. In construction, the complete hydraulic auto-climbing system climbs steadily without other lifting equipment and hence it is easy to handle. Besides, the climbing process is fast and safe. The hydraulic auto-climbing system is the best choice for high-rise building and bridge construction.

In today’s article, we are going to introduce our hot-sale product from the following aspects:

•Advantages in construction

•Structure of Hydraulic Auto-Climbing Formwork System

•The Climbing Workflow of LG-120

•Application of Hydraulic Auto-Climbing Formwork LG-120

Advantages in Construction:

1)Hydraulic auto-climbing formwork can climb as a complete set or individually.The climbing process is steady.

2)Easy to handle, high security, cost-effective.

3)The hydraulic auto-climbing system once assembled will not be dismantled until the construction is finished,which saves space for the construction site.

4)The climbing process is steady,synchronous and safe.

5)It provides all-round operating platforms. The contractors do not need to set up other operating platforms,thus saving the cost on material and labor.

6)The error of structure construction is small. As work on correction is simple, the construction error can be eliminated floor by floor.

7)The climbing speed of the formwork system is fast. It can speed up the whole construction work.

8)The formwork can climb by itself and cleaning work can be done in situ, so that the use of tower crane will be greatly reduced.

9)The upper and lower commutators are important components for the force transmission between the bracket and the climbing rail. Changing the direction of the commutator can realize the respective climbing of the bracket and climbing rail. When climbing a ladder, the cylinder adjusts itself to ensure the synchronization of the bracket.

Structure of Hydraulic Auto-Climbing Formwork System:

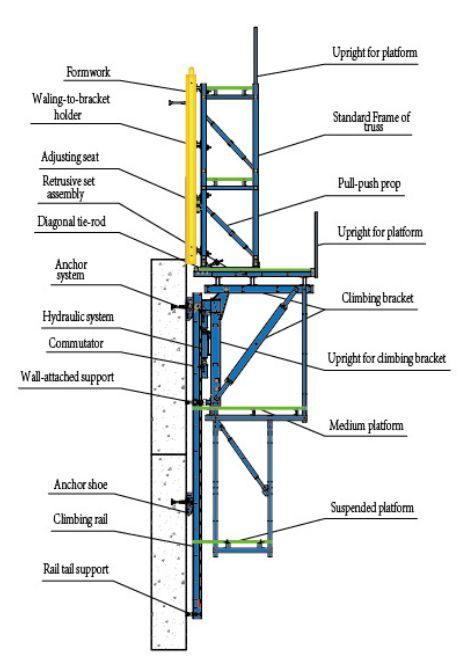

The hydraulic auto-climbing formwork system is composed of anchor system, climbing rail, hydraulic lifting system and operating platform.

The Climbing Workflow of LG-120

After the concrete is poured→Dismantle the formwork and move backward→Install the wall-attached devices→Lifting the climbing rail→Jacking the bracket→Tie up the rebar→Dismantle and clean the formwork→Fix the anchor system on the formwork→Shut the mould→Cast concrete

a.As for pre-embedded anchor system, fix the climbing cone on the formwork with the mounting bolts, wipe the cone in the cone hole with butter and tighten the high-strength tie rod to ensure that it cannot flow into the thread of the climbing cone. The anchor plate is screwed on the other side of the high-strength tie rod. The cone of the anchor plate faces formwork and the climbing cone is the opposite direction.

b.If there is a conflict between the embedded part and the steel bar, the steel bar should be properly displaced before the mould is closed.

c.To lift the climbing rail, please adjust the reversing devices in the upper and lower commutators to be upward at the same time. The upper end of the reversing device is against the climbing rail.

d.When lifting the bracket, the upper and lower commutators are adjusted downward at the same time, and the lower end is against the climbing rail (The hydraulic console of the climbing or lifting rail is operated by a specialized person, and each rack is set up to monitor whether it is synchronized. If it is out of sync, the hydraulic valve control can be adjusted. Before the bracket climbs, the vertical distance between the columns is 1m, and the vertical distance is 1m. Then, the 2cm wide tape is used to mark, and the laser level is installed to rotate and emit laser to quickly observe whether the frame is synchronized) .

After the climbing rail is lifted in place, the wall attachment device and climbing cone of the lower layer are removed and used for turnover. Note: There are 3 sets of wall attachments and climbing cones, 2 sets are pressed under the climbing rail, and 1 set is turnover.

Application of Hydraulic Auto-Climbing Formwork System:

Post time: Jan-14-2022