One of Hottest for Flexible Formwork For Concrete - Plastic Wall Formwork – Lianggong

One of Hottest for Flexible Formwork For Concrete - Plastic Wall Formwork – Lianggong Detail:

Advantage

Plastic formwork is a new material formwork system made from ABS and fiber glass. It provides project sites with convenient erection with light weight panels thus are very easy to handle.

Plastic formwork obviously improves the efficient forming of walls, columns, and slabs using a minimum number of different system formwork components.

Due to the perfect adaptability of each part of the system, the leakage of water or newly poured concrete from different parts is avoided. In addition, it is the most labor-saving system because it is not only easy to install and insert, but also light-weight compared to other formwork systems.

Other formwork materials (such as wood, steel, aluminum) will have various disadvantages, which may exceed their benefits. For example, the use of wood is quite expensive and has a major impact on the environment due to deforestation. It also saves your cost greatly compared with other material formwork systems.

Excluding the material, our developers focussed on ensuring that the formwork system was easy to handle and understand for users. Even less experienced operators of formwork systems are able to work with plastic formwork efficiently.

Plastic formwork can be recycled, in addition to reducing processing time and improving reusability indicators, it is also environmentally friendly.

In addition, the plastic template can be easily washed with water after use. If it breaks due to improper handling, it can be sealed with a low-pressure hot air gun.

Product Details

| Products name | Plastic Wall formwork |

| Standard sizes | Panels: 600*1800mm, 500*1800mm, 600*1200mm, 1200*1500mm, 550*600mm, 500*600mm, 25mm*600mm and etc. |

| Accessories | Lock handles, tie rod, tie rod nuts, reinforced waler, adjustable prop, etc… |

| Services | We can provide you suitable cost plan and layout plan according to your structure drawing! |

Feature

* Simple Installation& Easy deassembly.

*Separated easily from concrete,no need release agent.

* Light weight and safe to handle, easy cleaning and very robust.

* Plastic formwork can be reused and recycled for more than 100 times.

*Can bear fresh concrete pressure up to 60KN/sqm with proper reinforcement

* We can offer you site engineering service support.

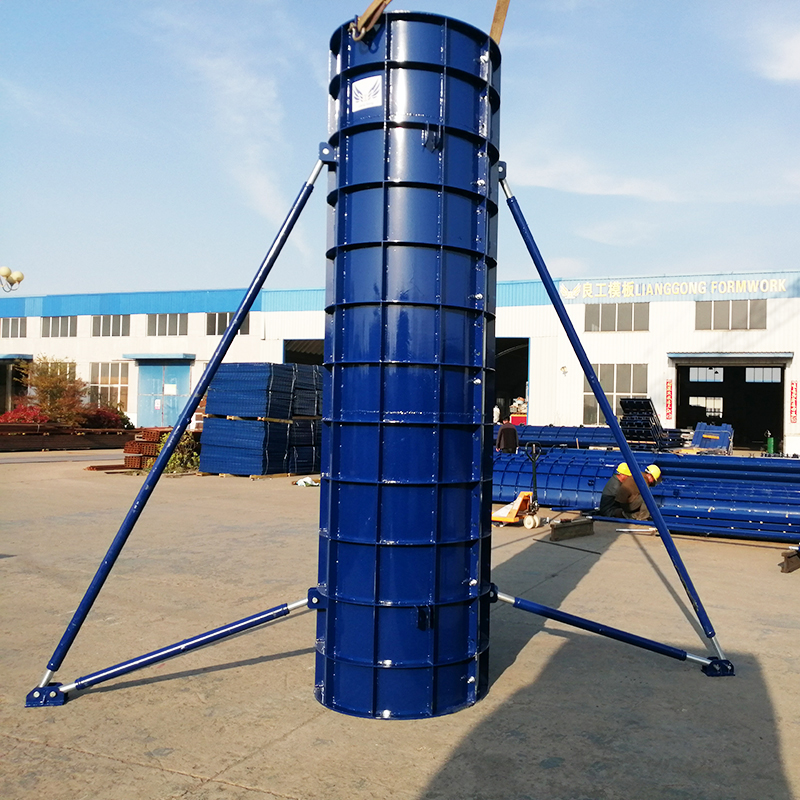

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got become among essentially the most technologically innovative, cost-efficient, and price-competitive manufacturers for One of Hottest for Flexible Formwork For Concrete - Plastic Wall Formwork – Lianggong , The product will supply to all over the world, such as: Costa rica, Rio de Janeiro, Malaysia, Our company always committed to meet your quality demand, price points and sales target. Warmly welcome you open the boundaries of communication. It is our great pleasure to service you if you need a trusted supplier and value information.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.